Best practices for failure analysis

Problem, Failure, and Solution codes are powerful tools for analyzing asset failure and automating work order routing. But, truth be told, not many MC users know how they work, much less use them. That's why we wrote this article.

Life Without Problem, Failure and Solution Codes: 2 Scenarios

Life Without Problem, Failure and Solution Codes: 2 Scenarios

Scenario #1: You're scanning a Work Order report for X-Ray machines, reading the Reason field for each Work Order to try to discern the most common issues that have placed the machines out of service.

Efficient failure analysis? Hardly.

Scenario #2: You have one technician that knows how to fix electrical issues with X-Ray machines. Every time a Work Order shows up for an X-Ray, you check the Reason field, figure out if there is an electrical issue, and then decide if your one X-Ray electrician guru should be assigned to the Work Order.

Best method for Work Order routing? Again...not so much.

Life With Problem, Failure and Solution Codes: Improved Failure Analysis

Life With Problem, Failure and Solution Codes: Improved Failure Analysis

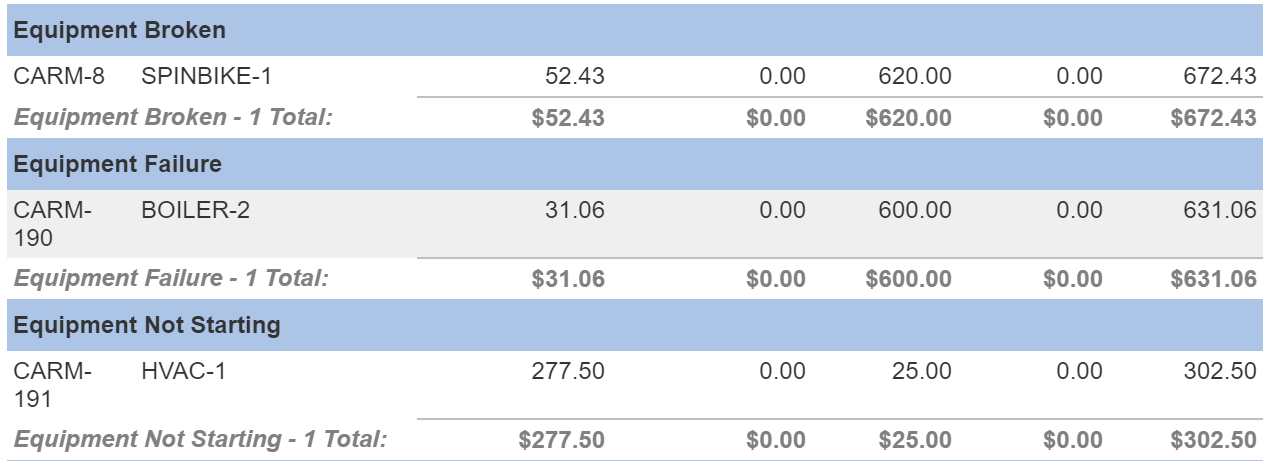

Problem, Failure and Solution codes allow you to not have to rely so heavily on the Work Order Reason for the above two scenarios. They improve failure analysis by systematizing errors/problems rather than relying on the generic nature of the Reason field. Place Problem codes in a Category, use the codes in our Reporter in conjunction with reports for Mean Time Between Failure, Work Order Costs, etc., and you're well on your way to an excellent Asset failure analysis program:

Life With Problem, Failure and Solution Codes: Automated Work Order Routing

Life With Problem, Failure and Solution Codes: Automated Work Order Routing

Problem codes are one of the most efficient ways to automate Work Order routing. You can input Problem codes on the Work Order Details tab, which then allows you to automatically route these Work Orders for particular Problems to particular personnel, checklist items, tools, and more.

Here are a few ways Problem codes can be used to drive Work Order routing:

- Link a Procedure to a Problem code so that you can have a particular task list paired with a particular maintenance issue.

- Link a Problem code to an Asset to automatically populate the Asset on a Work Order--or the other way around--locate Problems specifically associated with the Asset and add the correct Problem to the Work Order.

- Propagate the Repair Center and Shop to make sure the Work Order is routed to the proper personnel.

- Limit service requests to a few Problem codes to route these requests more efficiently.

It's Not All Rainbows and Butterflies...

It's Not All Rainbows and Butterflies...

...it's not all rain clouds and gnats, either. But, there are definitely some parameters to configuring and using Problem, Failure and Solution codes without which it is hard to gain the aforementioned benefits. And there are a few limitations in the current functionality of these codes. More on all this in a bit.

First, the next segments give some nice step-by-step instructions to using Problem, Failure and Solution codes in Maintenance Connection.

How to Create Codes

How to Create Codes

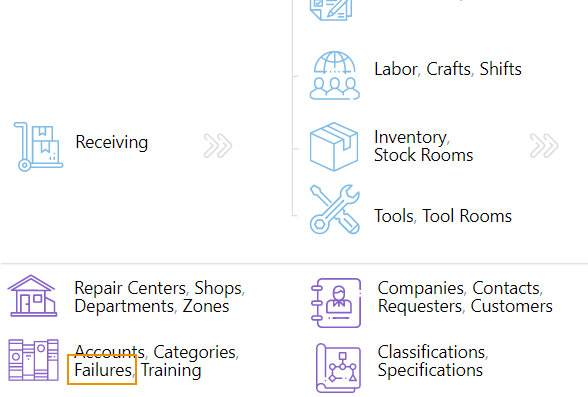

Access the Failures Module

Access the Failures Module

To configure Problem, Failure and Solution codes, access the Failures module from the Module Menu. Note that, even though this is called the Failures module, we configure all three types of codes in this module. There are not separate Problem and Solution modules.

Create a New Problem Code

Create a New Problem Code

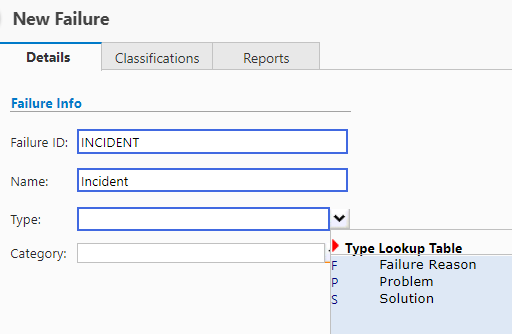

After accessing the Failures module, we'll create a new record by clicking the New button.

We'll input an ID and Name, and then we'll select a Type. The Type field is where we configure the record as a Problem, a Failure Reason, or a Solution.

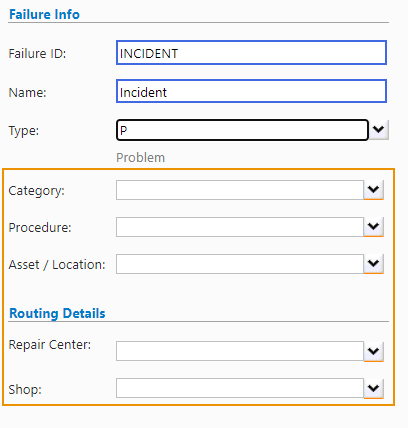

Problem codes are meant to drive Work Order routing (as well as potential Failure Reasons and Solutions). This is why, when we select the Problem option as the type, several other fields display.

How to Configure Codes

How to Configure Codes

Add a Category to a Problem Code

Add a Category to a Problem Code

The Category field is a grouping mechanism for Problem codes, useful for locating these codes in a lookup and for failure analysis reporting based on Category. For this example, we'll use Mechanical as the Category.

When it comes time to add this new Problem code to a Work Order, we can select the Mechanical category on the left side of the lookup, and more easily locate the Incident Problem.

You can imagine how adding categories can also be useful for reporting purposes, allowing you to categorize Problem codes and revealing which Category of Problem is showing up most often, which one is most expensive, etc.

Warning: Despite the Category field displaying for Failure Reasons and Solutions, we recommend that you not apply categories to these types of codes. Doing so increases the possibility of mixing categories on a Work Order (e.g., a Problem code in the Mechanical category and a Failure Reason in the Janitorial category), which in turn would damage reporting data.

Add a Procedure/Task List to a Problem Code

Add a Procedure/Task List to a Problem Code

The Procedure field lets you add a Task list for technicians to perform in response to a specific Problem. But, beyond that, Procedures are multi-faceted and highly configurable. Using this field can automatically propagate a lot of other information to Work Orders, based solely on the Problem.

Note: For more information on using Procedures, check out the How to Use Procedures article.

We'll add the Incident Response Procedure to this Problem code. This Procedure includes a Task list as well as a technician assigned with estimated labor time and cost.

Now, when we add the Incident Problem to a Work Order, the Procedure will automatically populate, along with the Task list (in the Tasks tab) and labor assignment.

Tip: You can also auto-assign technicians based on a Problem code via the Asset/Location field. You can choose the assignment method that best suits your business processes, but auto-assigning via a Procedure gives the added benefit of assigning technicians based on the specific issue with the Asset, rather than being more generally assigned based on the Asset itself, no matter what issue has arisen with it. Also, keep in mind that auto-assignments based on Procedures will override auto-assignments based on Assets.

Add an Asset/Location to a Problem Code

Add an Asset/Location to a Problem Code

The Asset/Location field lets you tie the Problem code to a specific Asset. In this case, we'll add a Spin Bike Asset.

With this in place, the following two processes are possible:

- If you add the Asset to the Work Order, the Problem field will automatically populate with the associated Problem (along with any other configurations made for the Problem).

- Or, vice versa: if you add the Problem to the Work Order, then the Asset will automatically populate along with all of its configurations.

You can only have one Problem associated directly to an Asset. So, if an Asset always has the same Problem (or, if for risk aversion, you always have to rule out a single Problem initially), it would be best to use this field. You may not want to use this field if you do not want Work Orders for this Asset to always have fields populated based on the associated Problem. Instead, we recommend adding Asset Classifications to the Problem, which we will discuss right about now...

Add an Asset Classification to a Problem Code

Add an Asset Classification to a Problem Code

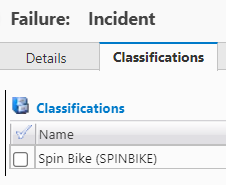

To associate a Problem code with an Asset Classification, select the Classifications tab and add the desired Asset Classification there. In this example, we'll add the Spin Bike Classification:

With this in place, we can add a Spin Bike type Asset to a Work Order, and then select the Problem field's dropdown arrow to open the Failures lookup. Selecting the Only Problems for Spin Bike checkbox displays the Problems that can be associated with Spin Bike Assets.

As opposed to using the Asset/Location field, using Classifications lets you have multiple Problems that can be associated with a single Asset. If you need to be able to choose from multiple Problems for an Asset on a Work Order, associate the Problem with a Classification rather than an Asset/Location. You can also add Problem codes to Classifications in the Failures tab of the Classifications module.

Add a Shop and Repair Center to a Problem Code

Add a Shop and Repair Center to a Problem Code

You can use the Shop and Repair Center fields to add more Work Order routing configurations to the Problem code. This is a simple way to make sure particular Problems are being addressed by the right personnel.

Once these fields are defined, we can add the Problem to a Work Order, and the Shop and Repair Center fields for that Work Order will automatically populate.

Add Problem Codes to the Service Requester

Add Problem Codes to the Service Requester

Selecting the the Available for Service Requests checkbox allows people to choose this Problem when they are submitting a service request, thus automatically routing the request based on how you've configured the Problem code in the Main Application (MRO).

Tip: Some organizations make the Problem a required field for service requests, and then make a select handful of Problems available for service requests. This limits the Problems for which people can submit a request and automatically routes these requests based on the Problem chosen.

How to Use Codes

How to Use Codes

Add Problem Codes to a Work Order

Add Problem Codes to a Work Order

Now that we know how to configure a Problem code and have talked about what happens when you add a Problem to a Work Order, it's time to tackle how you actually do this.

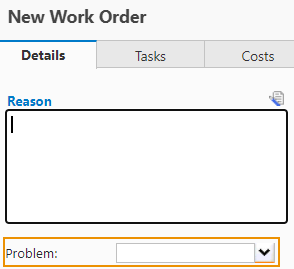

To add a Problem code to a Work Order, simply click the dropdown arrow for the Problem field on the Work Order Details tab. (Or, if you already know which Problem you want to add, start typing the Problem Name into the field, and the system will validate the chosen code):

Selecting the dropdown arrow opens the Failures lookup. This is where you will choose the Problem code for the Work Order. To do so, select the desired Problem and click the Apply button.

As mentioned above, you can select a Category on the left side of the lookup to display all the Problem codes associated with that Category.

Or--also mentioned above--if you've already added an Asset to the Work Order, you can select the Only Problems for [Classification] checkbox to display Problem codes associated with the Classification for the Asset. In this example, we have added a Spin Bike Asset to the Work Order, so we can choose to display only Problems associated with the Spin Bike Classification.

Once you have selected a Problem and clicked the Apply button, the Problem code will display in the Problem field and any other fields associated with the Problem will automatically populate.

Add Failure and Solution Codes to a Work Order

Add Failure and Solution Codes to a Work Order

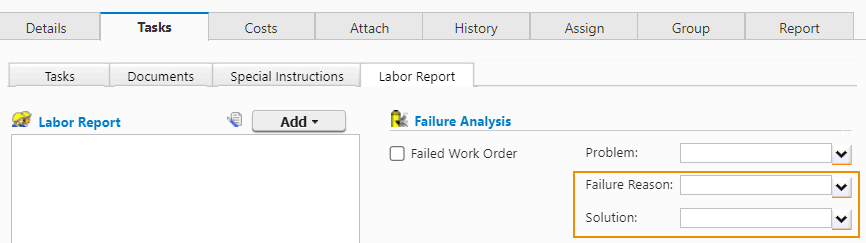

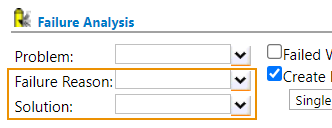

You will notice that only Problem codes can be added to the Details tab of a Work Order. This is because Problem codes can drive Work Order routing (Procedures, auto-assignments, etc.), but Failure Reasons and Solutions cannot. Instead, Failure Reasons and Solutions are meant to be defined in response to Problems, and thus are defined in the process of fulfilling a Work Order. You can add these codes in two places.

-

The Tasks>Labor Report sub-tab

-

The Complete/Close dialog in the Failure Analysis section

Report on Problems, Failures and Solutions

Report on Problems, Failures and Solutions

Using Problem, Failure Reason and Solution codes as intended opens up a treasure trove of data for failure analysis reporting. You can add Failure fields to Work Order and Asset reports as needed, but here are a few reports that our experts see as especially suited to failure analysis.

- Closed Work Order List by Failure

- Mean Time Between Failure

Parameters and Limitations

Parameters and Limitations

Failure Analysis Parameters

Failure Analysis Parameters

We've mentioned a lot of the uses and benefits of Problem, Failure and Solution codes, but in order to enjoy these benefits, it's important to keep a few parameters in mind:

Protect the Logical Progression of Codes

If you've read everything in this article up to this point (first of all, kudos!), you'll probably have noticed a logical progression for Problem, Failure and Solution codes. If you think of these codes in terms of a maintenance story, it makes a lot of sense. You initiate a Work Order based on a Problem, a Failure Reason defines why the Problem occurred, and a Solution addresses the Failure Reason. So, it works like this: Problem > Failure Reason > Solution.

For example: Problem=Incident Reported > Failure Reason=User Error > Solution=User Error Training

With this in mind, the overarching rule for using these codes is to protect the integrity of this maintenance story, the logical progression from Problem to Failure Reason to Solution.

It is best for Problem codes to be more general and for Failure Reasons to be more specific. Ideally, there would be a handful of specific Failure Reasons that fit logically beneath the umbrella of a more general Problem. Likewise, there should be a handful of Solutions that could logically address the Failure Reason.

Don't Mix Categories on a Work Order

If you have assigned Problem codes to a Category, it is important that you not use Failure Reasons or Solutions that belong to a different Category (I.e., a Category other than the one associated with the Problem) within the same Work Order. Doing so will damage reporting data for failure analysis because the system will not be able to recognize the proper Category for each Work Order.

Because of this, we recommend that you not assign Failure Reasons or Solutions to a Category. This will protect you from adding Failure Reasons or Solutions that belong to a Category different from the Problem code.

Limitations of Failure Analysis with MC

Limitations of Failure Analysis with MC

We want to make you aware of a few limitations we see in the current functionality of Problem, Failure and Solution codes. We see these limitations as a gap between what we recognize as best practices and the ease with which those best practices can be implemented. For example:

- There are no dependencies imposed by the system to protect the logical connection between codes. We recommend implementing dependencies so that only certain Failure Reasons can be chosen in response to a Problem, and only certain Solutions can be chosen in response to a Failure Reason. Currently you must impose these dependencies manually.

- You have the option to populate the Problem code on a Work Order based on an Asset, but it would be optimal to be able to populate the Problem code based on other fields, especially the Work Order Type field. This option is not currently available.

- It is best practice to not assign a Category to Failure Reasons or Solutions; however, the Category field displays prominently for these codes rather than being hidden like other fields that are only definable for Problem codes. There is also no access rights setting that allows you to make Category a read-only field.

We believe you can use the best practices and guidelines provided in this article to add and/or optimize your failure analysis as an organization. Related articles on this topic would include the Import Common Healthcare Failure Codes article which provides more than 170 healthcare failure codes you can add to your system.